- Home

- About Us

- Group Companies

- Products

- Gallery

- Contact Us

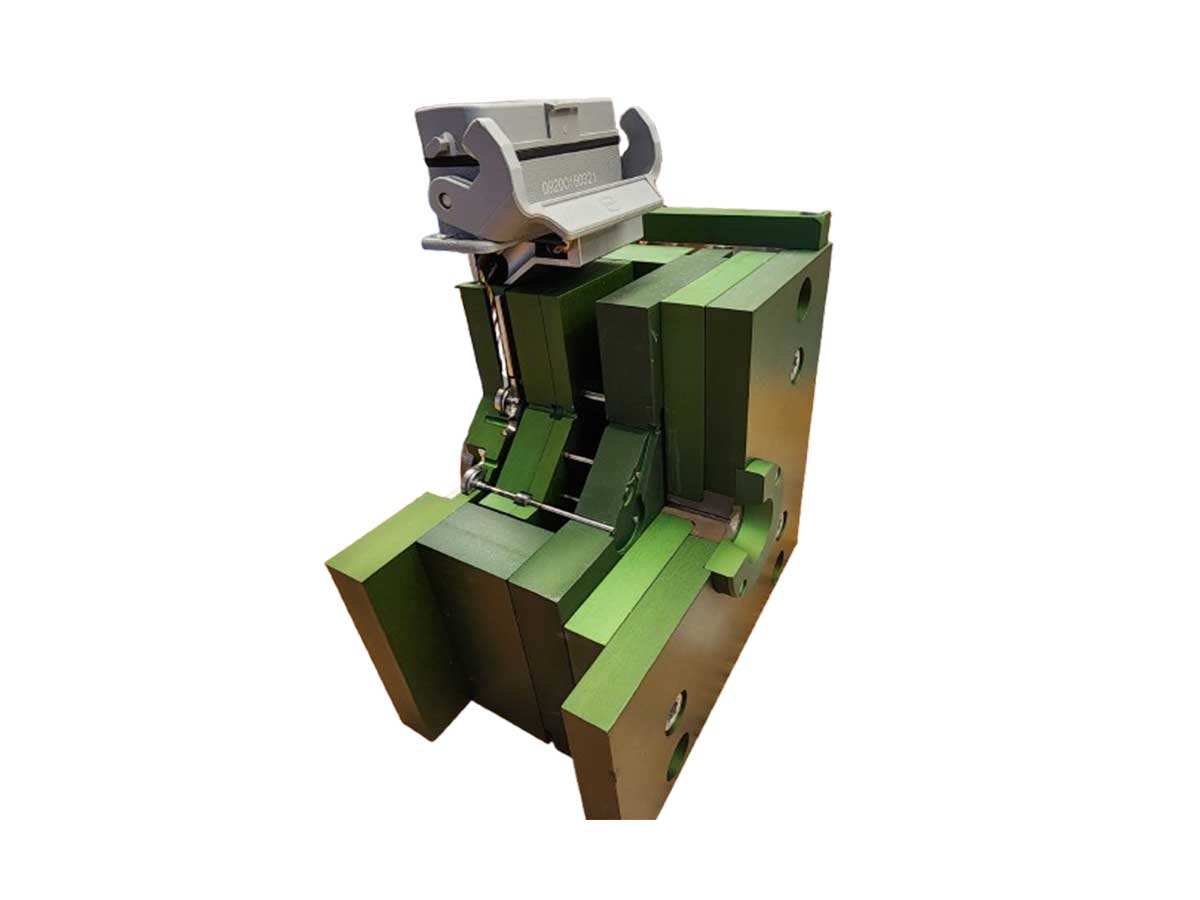

The Cavity Eye and Hungry Pressure Monitoring System is a cutting-edge technology designed to enhance the precision and efficiency of injection molding processes. The Cavity Eye system provides real-time monitoring and analysis of cavity conditions during the molding cycle, allowing for immediate detection of defects or inconsistencies in the molded parts. Meanwhile, the Hungry Pressure Monitoring System ensures accurate control and regulation of injection pressure, optimizing the filling process and preventing issues such as short shots or overpacking. Together, these systems offer advanced diagnostics and process control, enabling manufacturers to improve product quality, reduce waste, and achieve consistent production results.